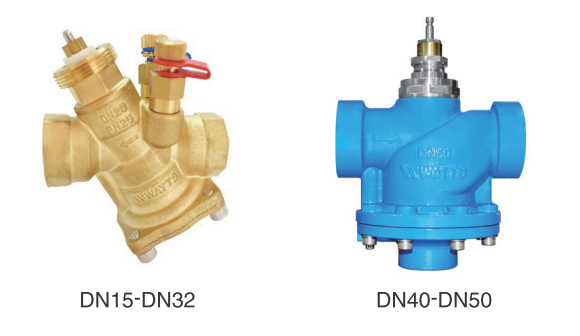

PICV DN15-50

- The Watts pressure independent control valve is designed for terminal equipment in AHU, PAU or MAU system to regulate the flow through the valve as well as to keep the constant differential pressure at both ends of the valve

- Constant differential pressure between the two ends of the control valve

- Equal percentage flow characteristics with actuator

- Preset maximum flow rate to facilitate on-site debugging

- Designed with front and rear differential pressure measuring nozzles

- Dust-proof O-ring design & O-ring on disc for zero leakage

- PN25

- DZR brass body (DN15-32), ductile iron body (DN40-50)

- Connections to ISO 7/1 (BSP)

Electric Actuators (for DN15-50)

- Used in auto-control system to regulate the opening rate of W-PICV valve body

- Modulation Type W-AR2M with feedback signal

- On-off Type W-AR1S

- IP54 protection

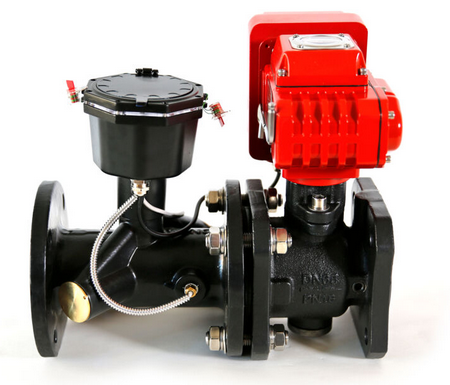

PICV DN65-250

- Equal percentage flow characteristic

- Constant differential pressure is achieved

- Self-balancing valve core realizes easy shutoff

- V-ring sealing and self-compensating spring result in higher abrasion resistance and longer service life

- Electronic preset of maximum flow facilitates on-site commissioning

- Fault auto-detection and alarm function

- Overload protection for power supply, Stroke auto-detection

- Manual lever for convenient on-siting commissioning and troubleshooting

- Spring is cut off from the water, longer service life

- PN16 / PN25

- Working differential pressure: 30-400kPa (DN65-150), 35-400kPA (DN200-250)

- Flow deviation ±5%

- Flange connection standards: equivalent to BS EN 1092-2

- IP54 protection grade

- Used in conjunction with W-A11 actuator – modulating with feedback signal

DN65-150

DN200-250

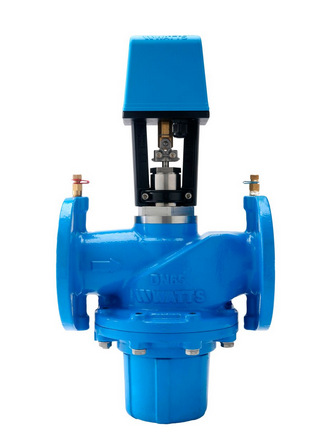

Intelligent Control valve DN15-150

- W-SCBV series intelligent control valves serves for fluid control applications such as central air conditioning, heating, water treatment, etc. It is a set of pressure-independent products integrated with energy meter sensor technology, intelligent actuator and control valve

- Integrated Bluetooth, analog signal, Modbus RTU and BACnet MS/TP control

- Monitoring both on site and remotely

- Integrated multiple control modes

- Protection level: IP67

- PN20 (DN15-50, PN16 (DN50-150)

- Brass body (DN15-50), ductile iron body (DN50-150)